Moving a warehouse and increasing stor

BusMarket Group (BM PARTS) is the distributor company № 1 in western Ukraine for the sale of spare parts for cars and light commercial vehicles. The main office is located in Lutsk. In addition, the company has 2 regional hubs in Lutsk and Kyiv and 8 warehouses in different cities of Ukraine, such as Vinnytsia, Lviv, Ivano-Frankivsk, Chernivtsi, Khmelnytskyi, Khust, Dnipro and Rivne.

The company cooperates with more than 100 brands and has more than 80 thousand items in various price ranges from premium brands to private labels. The area of all BusMarket Group (BM PARTS) warehouses is more than 16 thousand m2. And delivery of orders is carried out in 500 settlements.

At the beginning of 2021, the central warehouse moved to a larger building. And because of this, there was a need to increase the number of sections and storage space.

BusMarket Group (BM PARTS) requested KAPELOU with the following main tasks:

- extend carton live storage racks for the order sorting area;

- increase the number of shelf racks;

- integrate new equipment with the warehouse management system (WMS).

KAPELOU® manufactures equipment consisting of modules that allow you to easily change the configuration of the warehouse or increase the scale of production by adding the necessary sections. Also, this is very convenient during the relocation. The equipment does not need to be completely disassembled and then reassembled. Individual modules are easily mounted in the new configuration and connected to the warehouse management system.

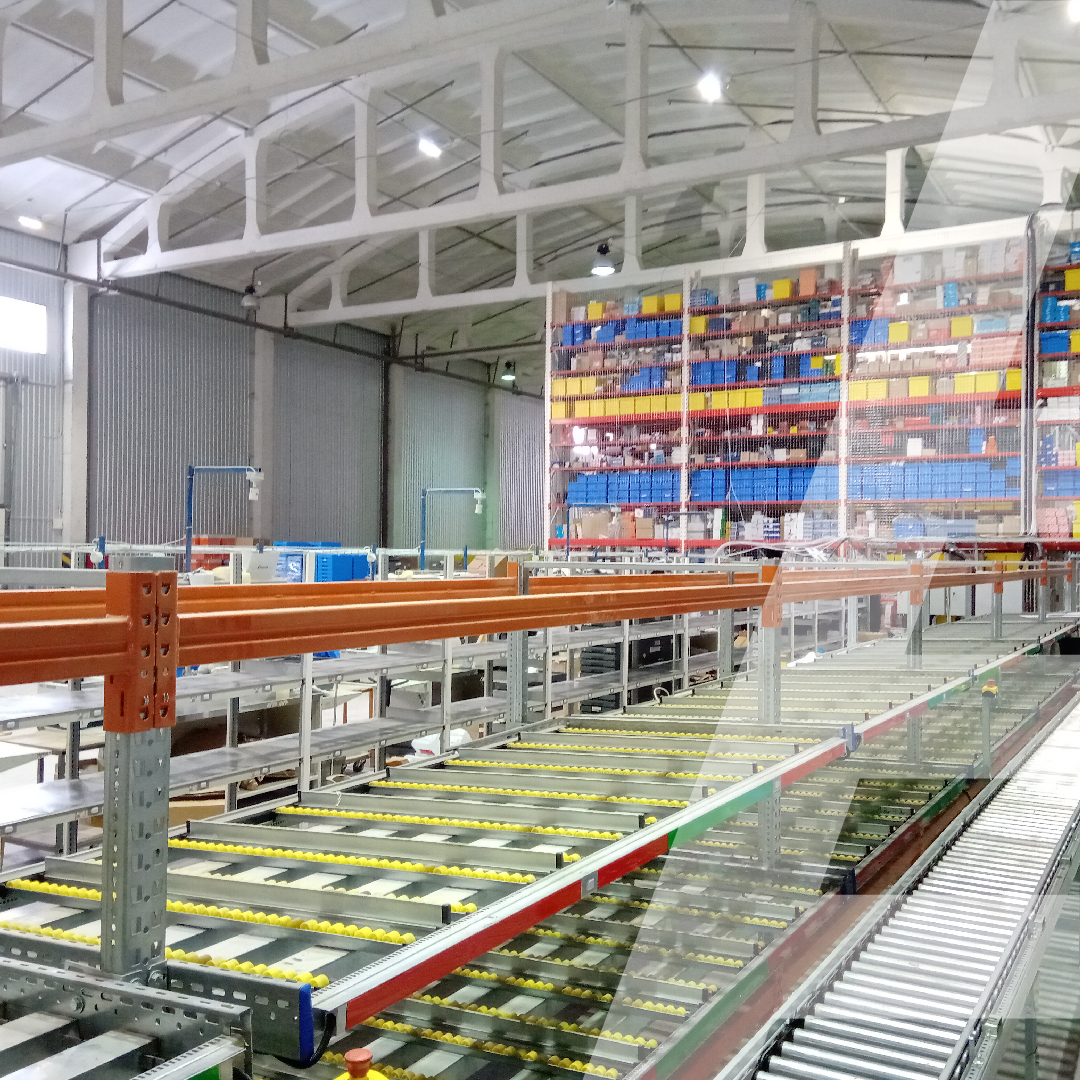

Our specialists have developed, manufactured, assembled and performed commissioning work of the necessary equipment for automation of this part of warehousing processes:

- 2 modules of carton live storage racks for a zone of sorting of orders with a width of 3 040 mm;

- 4 sections of shelf racks for storage and assembly of cargo on 20 shelves, with a maximum load of 500 kg per section;

- installed a controller of the Pick-to-Light AT500, which provides control of transportation of goods for 120 modules;

- integrated new equipment with the existing WMS.

Thanks to additional modules of the gravity system and shelf racks, the process of sorting orders has been significantly accelerated. There is additional space for storage and assembly of goods, and work has become more comfortable.

The peculiarities of this project include changing the configuration of racking and automated systems when moving to a new warehouse with maximum use of existing equipment and minimum additional costs for the client, taking into account the differences between “old” and “new” warehouses. Also, change the configuration of the existing belt conveyors of the client – from inclined to straight belt.

We thank BusMarket Group (BM PARTS) for many years of cooperation and interesting projects.

Close

Close

Back

Back

Close

Close