Smart roller conveyors: efficient and modern warehouse transport

Warehouse logistics is evolving rapidly. Companies are looking to streamline product movement, improve coordination between warehouse zones, reduce manual labor, and eliminate order processing delays. A proven, cost-effective answer to these challenges? Carton and pallet smart roller conveyors.

According to forecasts from WiseGuy Reports, the global carton and pallet roller conveyor market is projected to reach $6.5 billion by 2032. This growth is driven not only by the demand for automation technologies, but also by the need to cut operational costs and accelerate pallet and carton handling systems.

Inefficient internal transport is often the main obstacle to consistent throughput and warehouse scalability. At KAPELOU roll case conveyor factory, we’ve spent over 12 years helping our clients automate warehouse transportation, maintain steady order fulfillment speeds, and free up resources for further business growth. We don’t just manufacture roller and belt conveyors – we deliver integrated conveyor solutions based on roller and belt transport systems that optimize operations and minimize unnecessary overhead.

In this article, we’ll explore why the pallet or carton conveyor system is a key component of warehouse logistics – and how they can transform the way your facility handles internal transport.

Pallet and carton conveyor system: the backbone of modern warehouse infrastructure

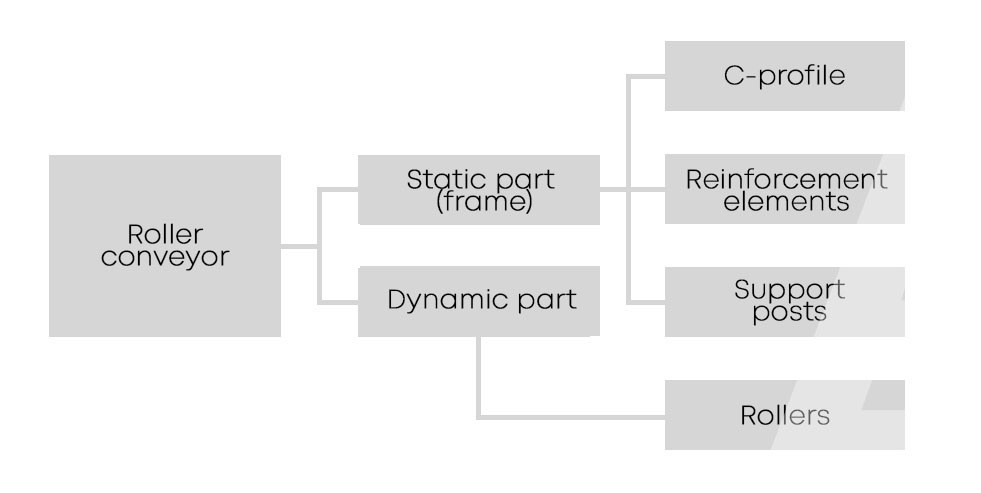

Roller conveyors (also known as gravity or powered conveyors) are essential warehouse roller systems that enable the mechanical or automated movement of totes, cartons, boxes, and pallets via interconnected, synchronized conveyor elements. Each unit features parallel rollers mounted within a sturdy frame, with guide rails to ensure stable and controlled load movement. Designed for durability and long-term performance, the conveyor for boxes, carton and pallets rely on a simple yet robust metal structure, making them a reliable foundation for modern warehouse automation.

Depending on the drive mechanism, roller conveyors are divided into two main types:

- gravity roller conveyors (non-powered): for accumulation zones, tote and carton return lines, or manual picking areas. These conveyors rely on a slight incline and manual force to move the load – no electricity required. The gravity conveyor for boxes offers energy-free transport and requires minimal maintenance, making them a cost-effective choice for basic intralogistics.

- powered roller conveyors: designed for zones with high throughput, pallet and carton roller conveyor is equipped with electric motors to ensure controlled, consistent movement of totes and pallets along the transport line. Depending on the application, they can be driven by chain, belt, or roller shaft – enabling precise control over speed, direction, and flow.

In both systems, rollers act as load-bearing wheels, supporting and guiding containers or pallets. Based on the product type and operating conditions, rollers are manufactured from different materials:

- steel rollers are built for heavy-duty load and industrial applications.

- plastic rollers are essential in pharmaceutical and food industries, where hygiene standards are critical.

- stainless steel rollers are ideal for wet or chemically aggressive environments, ensuring durability and compliance.

Powered roller conveyors are used to move boxes, cartons, totes, or fully loaded pallets. The configuration depends on the load type. Box conveyor systems have standard roller spacing and medium load capacity. Pallet conveyors are designed with reinforced frames and guide rails to ensure stability and load-bearing performance during heavy transport tasks.

Investing in high-quality pallet and carton roller conveyor means eliminating disruptions and inefficiencies in product movement. It ensures consistent warehouse performance with minimal manual input.

The KAPELOU warehouse roller conveyor provider integrates roller conveyors – both powered and gravity – along with belt and spiral conveyors to create fully synchronized systems across warehouse zones. We’ve implemented automation projects across Europe, in the U.S., and the Middle East. With experience from over 850 completed projects, we develop and deliver practical, full-scale automation solutions tailored to real-world challenges in modern warehouse logistics. Designed for compatibility with automated picking, AMRs, and WMS/WCS platforms, our roller and belt conveyors support smooth carton and pallet movement across warehouse zones – no bottlenecks, no downtime.

Powered pallet conveyors: reliable transport of heavy load

Pallet straight roller conveyor is the optimal solution to automate the transport of palletized goods. As a type of powered roller conveyor, pallet conveyors are essential in any warehouse dealing with heavy-duty load. Designed for robustness, powered pallet conveyors handle loads ranging from 150 to 2,000 kg per pallet thanks to their reinforced construction. Compared to standard carton and box conveyor systems, pallet conveyors are built with larger-diameter rollers and thicker roller walls, delivering enhanced strength and durability during continuous operation with heavy goods. Rollers are typically made of steel or stainless steel, ensuring long service life even in demanding industrial environments.

To ensure reliable performance and smooth motion, it’s crucial to purchase your pallet conveyor from a trusted supplier. As a zero pressure roller conveyor supplier, KAPELOU designs and produces high-performance pallet conveyors – built to automate transport between storage, processing, packaging, and dispatch zones. The straight roller conveyor is used to automate warehouses in diverse industries – from pharmaceuticals and food production to e-commerce and retail, where precision and reliability in goods movement are non-negotiable.

A pallet roller conveyor systems by KAPELOU offer:

- seamless integration with WMS, vertical lifts, automatic palletizers/de-palletizers, and other warehouse systems;

- scalability – conveyor modular design allows easy system expansion as your operations grow;

- durability – more than 10 years of service life with proper roller conveyor systems usage and regular maintenance;

- ZPA logic (zero pressure accumulation) – ensures collision-free movement by maintaining safe pallet spacing;

- automatic load balancing – evenly distributes palletized goods across conveyor zones;

- accumulation functionality – in case of temporary stoppage, pallets accumulate automatically without halting the entire system.

A carton and box roller conveyor: speed and precision at every meter

If your warehouse needs to automate the movement of carton boxes, plastic totes, or containers, a powered and gravity conveyor is a practical and scalable solution. Both types of carton conveyor belts feature a modular design that simplifies installation and system expansion.

Thanks to simple, robust, and effective conveyor systems for boxes – like the powered and non-powered carton and box roller conveyor manufactured by KAPELOU box roller conveyor factory – automation is now accessible for warehouses of any size. Warehouse roller conveyors optimize internal transport, help to automate manual labor, and increase productivity without large-scale investment.

A carton and box conveyor rollers by KAPELOU carton conveyor provider offers:

- energy efficiency – only active box and carton conveyor zones are powered, saving electricity;

- ZPA logic (zero pressure accumulation) – to automate spacing between items for preventing product damage and jams;

- reconfigurability – carton and box conveyor rollers layout can be easily adjusted to handle new types of transport units;

- smooth and safe operation – consistent and controlled product flow across the carton and box conveyors;

- quick installation and maintenance – carton and box conveyors modular design accelerates deployment and minimizes downtime.

Smart material flow control: total movement visibility

No warehouse automation system based on roller or belt conveyor is complete without intelligent control architecture. The KAPELOU zero pressure accumulation roller conveyor supplier designs roller and belt conveyor control systems as integrated hardware and software solutions, combining: PLCs (programmable logic controllers), HMI (human-machine interfaces), WCS (warehouse control systems) to bridge WMS and equipment, SCADA systems for real-time visualization, monitoring, and analytics.

This smart control approach enables:

- collision-free and congestion-free product movement;

- dynamic routing based on queue status, maintenance needs, or priority changes;

- automated barcode, QR code, and RFID tag scanning;

- safe operation across all conveyor zones;

- real-time equipment diagnostics and condition monitoring.

With intelligent controls, it is easy to automate even the most complex warehouse zones – ensuring smooth flow, operational precision, and fast adaptation to changing logistics conditions.

A box or pallet conveyor: the backbone to automate the intralogistics

A roller conveyor is a core component to automate the warehouse logistics. It serves as the critical link that connects every stage of pallet and carton handling systems into one unified, integrated system.

Key advantages of roller conveyor integrating into warehouse and production infrastructure:

- continuous flow – seamless load movement without delays, crucial for high-throughput environments;

- reduced handling time – a box or pallet conveyor helps to automate manual load transportation;

- cost efficiency – a box or pallet conveyor lowers operational expenses, minimizes wear on transport units, and reduces the risk of product damage;

- optimized space usage – a conveyor can be installed horizontally, suspended, or at an incline to fit spatial or architectural constraints.

Thanks to its simple yet flexible construction and compatibility with other warehouse systems, a pallet, box and carton roller conveyor industries are from e-commerce, retail, and distribution to pharmaceuticals, food production, automotive, and courier services. Whether you’re transporting small cartons, totes, or large pallets, KAPELOU roller and belt conveyors adapt to your workflow and maintain consistent carton and pallet handling efficiency even during peak loads.

Powered and gravity conveyor: enabling modern intralogistics technologies

A box or pallet conveyor enables the deployment of advanced automation technologies in environments where manual handling was previously the only viable (but inefficient) option.

Gravity and powered roller conveyor systems support:

- automated transport between key warehouse zones – by ensuring continuous and controlled carton and pallet flow, to automate manual handling and increase processing speed;

- Goods-to-Person order picking – a conveyor delivers items directly to operators to maintain a steady carton a pallet flow, enabling fast and accurate order picking while minimizing operator fatigue and human error;

- automated sortation – a conveyor redirects items to appropriate areas with speed and accuracy;

- return of empty totes to storage or picking zones;

- buffering – a conveyor temporarily accumulates load before packing, sorting, or shipping;

- vertical integration – a conveyor moves the load between mezzanines or floor levels with ease;

- automated packing and shipping – a powered conveyor moves completed orders to packing stations or outbound docks.

A box or pallet conveyor is the strategic equipment for implementing warehouse automation technologies. Its integration ensures a stable, uninterrupted load flow between zones – essential to automate order picking, synchronize operations, and eliminate bottlenecks.

A comprehensive approach: a roller conveyor as part of an integrated logistics ecosystem

Among the many options to automate internal logistics, a box or pallet conveyor stands out as one of the simplest yet most effective tools. There are two key logistics scenarios where they bring the greatest value: connecting core warehouse zones via roller conveyor lines, or seamlessly integrating them with other automation solutions to ensure smooth system-wide operations.

To unlock the full potential of the box or pallet conveyor, we recommend combining gravity and motorized conveyors within a multi-level warehouse automation system. This combination enables the creation of a smart logistics environment, where each component enhances the performance of the others – allowing for scalable growth in response to real market demands.

Below are several examples of how roller conveyor can be effectively combined with other warehouse technologies to automate manual labor, ensure uninterrupted material flow, and optimize transport routes regardless of load type:

- barcode scanners, dimensioning equipment, Pick/Put-to-Light systems + measuring roller conveyor: this combination enables precise load tracking, real-time flow control, fewer errors, and faster order picking.

- roller conveyor integrated with belt conveyors, vertical lifts, stacker cranes, and shuttle systems: to automate both horizontal and vertical load movement across multiple levels.

- pallet turntables + motorized pallet conveyor: these allow flexible changes in pallet flow direction for streamlined transport.

- roller conveyor + robotic technologies (automated picking and sorting systems, AMRs, AGVs): ensure continuous, accurate coordination between handling zones.

- warehouse conveyor rollers + automated workstations: powered by custom-designed software, operators gain full control over picking and sorting processes with detailed load, order, and packaging rule data – all within a single interface.

When integrated with other warehouse equipment, a box or pallet conveyor is no longer just a tool for efficient product movement – it becomes a strategic asset for organizing warehouse order picking in a cost-effective way.

Depending on the type of goods and transport logic, gravity and powered roller conveyors can be effectively combined with belt conveyors – ensuring smooth movement of both lightweight cartons and irregularly shaped items. For items with unstable bases or softer packaging, belt conveyors offer secure transport, while warehouse conveyor rollers handle standardized cartons and totes – together forming a balanced warehouse flow. KAPELOU systems integrate roller and belt conveyors to support a wide range of load types, providing flexibility for everything from small packages to heavy-duty transport. The result: a high-tech warehouse that runs without unnecessary expenses, delays in order picking, or physical strain on staff.

Expert advice from KAPELOU: how to choose a box and pallet conveyor that deliver

Selecting a box or pallet conveyor is a strategic decision – it directly impacts the overall performance of your operations. To ensure smooth and reliable box or pallet conveyor operation, our experts recommend evaluating the following critical factors:

- Frame material:

– Choose between stainless steel, structural steel, or high-strength polymers based on your operating conditions.

– Powder coating helps protect box and pallet conveyor metal components from corrosion, moisture, dust, and chemical exposure. - Roller quality:

– Pay attention to the type of bearings and their load-bearing capacity.

– Precise roller rotation ensures smooth load movement and extends the overall box and pallet conveyor service life. - Drive type:

– Decide between gravity or motorized conveyors depending on your logistics needs.

– Assess energy efficiency, drive reliability, and availability of variable frequency control. - Modular box and pallet conveyor design:

– Opt for a modular system that allows for reconfiguration, the addition of sections, curves, or inclines.

– Make sure the warehouse conveyor rollers are compatible with other elements of your infrastructure. - Engineering & Design:

– Properly calculate load capacities, transport speed, and roller type based on product specifications.

– Factor in peak load periods and building layout constraints during the box or pallet conveyor design phase. - Integration with WMS/WCS:

– Ensure the box or pallet conveyor is compatible with your existing IT infrastructure and supports standard communication protocols. - Supplier Expertise & Reliability:

– Look for a proven track record with box and pallet conveyor based solutions, deep understanding of logistics workflows, and accountability for results. - Warranty & Service:

– Prioritize suppliers that offer responsive technical support and post-warranty service to cover the entire lifecycle of box and pallet conveyor.

By choosing KAPELOU’s motorized and gravity conveyor, you get full engineering support from our team – from concept and production to seamless integration and long-term service. We use only certified, high-quality materials to ensure our roller and belt conveyor perform reliably, even under heavy-duty conditions.

Motorized and gravity conveyor: equipment to automate order picking

A box or pallet conveyor is more than just a transport line – it’s the backbone of your warehouse, to automate and connect all critical zones. Thanks to precision engineering, modularity, and intelligent control logic, KAPELOU’s gravity and motorized conveyor creates a steady, efficient workflow for the load of all types – from individual cartons and conveyor boxes to full pallets. Whether used independently or as part of an integrated automation system, our box or pallet conveyor is designed to automate order picking processes.

At KAPELOU, we develop pallet and box conveyor automation solutions based on our own manufacturing capabilities – tailored to meet today’s challenges and scalable for the future.

Automate your load transport processes today. Reach out to us, and we’ll help you select the ideal roller or conveyor belt drives for warehouses. KAPELOU – innovative technology and reliable pallet and box conveyor equipment, straight from the manufacturer!

Today, warehouse efficiency is measured in seconds, not hours. Modern warehouses are no longer just spaces packed with racks – they’re dynami...

On August 19-20, 2025, our engineering team completed training at Dambach Lagersysteme (Germany), a manufacturer of storage and retrieval equipment...

In recent years, the warehouse has evolved far beyond being just a place to store goods. It is now a dynamic, technology-driven environment –...

Close

Close

Back

Back

Close

Close