Automated stacker cranes: efficiency at every level of your racking

Today, warehouse efficiency is measured in seconds, not hours. Modern warehouses are no longer just spaces packed with racks – they’re dynamic hubs where speed, accuracy, and safety define success.

The explosive growth of e-commerce and same-day delivery expectations are pushing businesses to rethink order fulfillment. Random storage, picking errors, and slow material flow are risks you simply can’t ignore.

A stacker crane is a strategic choice for high-intensity storage. This solution enables maximum warehouse density (tall racking, narrow aisles) and ensures high-speed handling of large volumes of uniform goods. Automated stacker crane enables precise, vertical storage, guarantees quick and accurate load flow, integrates seamlessly with WMS and other warehouse systems, and automates picking.

Automated storage and retrieval systems (AS/RS) are a proven technology driving warehouse automation in Europe, where high-bay storage and compact logistics solutions are in high demand. According to Market Research Future, Europe’s AS/RS market is projected to grow 7-8% annually through 2030.

At KAPELOU, our automation project experience across industries shows that the market sets the rules. Labor shortages, sorting and picking errors, chaotic storage, underutilized vertical space, and risks associated with high-level operations directly impact productivity. Our automated stacker crane solutions maximize vertical storage, accelerate order fulfillment, and reduce manual labor, creating safer, more consistent working conditions.

So why invest in an automated stacker crane? Let’s break it down:

- What an automated stacker crane is and how it works;

- How this technology boosts picking speed and accuracy;

- Why it’s a long-term investment in operational efficiency and resilience.

What is the definition and applications of an automated stacker crane (AS/RS)?

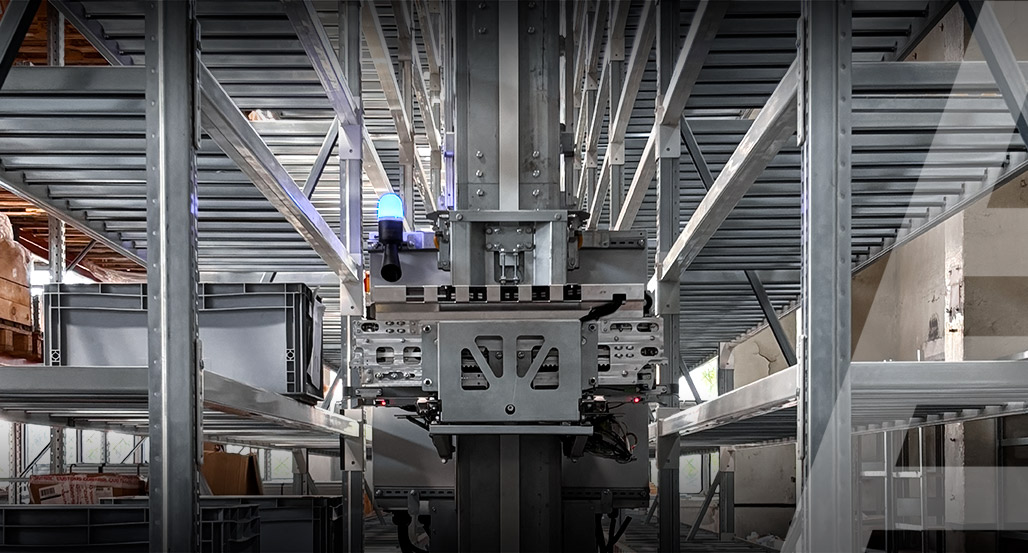

An automated stacker crane is an automated system for moving and storing goods vertically and horizontally. In warehouses with high product volumes, it’s one of the cornerstones of automation.

Thanks to automation, digitization, and integration into smart warehouses, AS/RS are warehouse equipment that is part of the global Logistics 4.0 concept.

The stacker cranes implementation becomes the main tool for scaling the warehouse without additional personnel costs. Integrating with WMS allows you to synchronize the material flow: from the moment an order is received to its shipment.

A racking automated stacker crane delivers:

- maximized storage capacity thanks to integration with shuttle systems without building out more space;

- automated storage and retrieval: precise positioning allows the automated stacker crane to move loads along predefined routes without an operator;

- safety: stack goods high without risking drops, collisions, overloading, or product damage;

- WMS integration: automatically identifies optimal storage locations and tracks inventory in real time;

- reduced human error: handling physically demanding, repetitive tasks, cutting labor costs;

- scalability: adapts easily as your warehouse logistics grows or SKU mix changes;

- energy efficiency and long-term ROI: regenerative drives and optimized motion allow lights-out operation, reducing lighting and climate control costs;

- automation that allows the warehouse to operate continuously 24/7;

- compliance with Logistics 4.0 principles – automation, digitization, and real-time analytics.

How do the automated stacker cranes save space?

Automated stacker cranes combine lifting (like a crane) and storage placement (like a stacker). They place pallets and cases vertically across racking levels, fully utilizing warehouse height. The result: higher storage capacity without expanding the footprint.

How do rack automated stacker cranes operate?

- Load pickup: the crane grabs a pallet or case and positions it on the carriage.

- Vertical movement: the mast lifts the load to the required rack height via motor, chain, or linear guide.

- Horizontal movement: the automated stacker crane moves along racks using rails or rollers to deliver the loads.

- Load placement: the carriage stacks the product on a pallet or rack shelf.

- Return to start: ready for the next cycle.

What are the main types of rack automated stacker cranes for different warehouse logistics?

For warehouse logistics with diverse SKUs and limited floor space, racking automated stacker cranes are indispensable:

- pallet racking stacker cranes: ideal for large loads with direct access to each pallet. Such rack AS/RS are common in distribution centers, logistics hubs, and production lines automation. Benefits: high reliability and optimal use of vertical space.

- racking stacker cranes for boxes: designed for small items and high-SKU orders. Box rack Miniloads provide fast access and high storage density, boosting picking speed for small orders. Stacker cranes for boxes are widely used in e-commerce, pharma, and retail automation projects.

Large logistics centers often combine both racking types for full warehouse logistics automation: pallet stacker cranes for bulky goods and Miniload case stacker cranes for small parts.

How automated racking equipment accelerates warehouse logistics?

Modern warehouse logistics is a high-speed automated ecosystem where every element counts.

Racking automated stacker cranes enable:

- automated small-item racking storage: high density, fast access;

- shuttle systems assisted multi-level storage: racking automated stacker cranes access levels, shuttle systems reach deep into channels. In automated warehouses, an automated storage system can work together with a pallet shuttle system, which acts as an auxiliary trolley inside the rack;

- Goods-to-Person delivery: containers or trays arrive automatically at picking stations;

- robotic integration: AMRs and AGVs receive loads from high storage racking for continuous material flow;

- conveyor and sorter integration: automated sorting and routing of orders flow;

- real-time rack inventory management: WMS/WCS integration optimizes pallets and boxes flow routes and monitors storage process.

Shuttle system + automated storage system: double efficiency for pallet warehouses

One of the most effective automation concepts for modern pallet warehouses is the combination of AS/RS with a pallet shuttle system. While AS/RS handles high-speed vertical and horizontal movements across multiple storage levels, the automated pallet shuttle takes over inside deep racks, transporting orders quickly and safely along the channels.

This synergy allows companies to:

- maximize storage density without sacrificing accessibility;

- reduce pallet handling time through automated pallet shuttle movement;

- achieve continuous 24/7 warehouse flow with minimal human intervention;

- integrate both systems into WMS for real-time inventory control.

Compared to standalone solutions, AS/RS with automated pallet shuttle technology delivers higher throughput and scalability. Businesses benefit from faster order processing, better use of available floor space, and lower operational costs.

Whether you operate a high-bay warehouse or a logistics center with fast pallet turnover, combining automated pallet shuttle with AS/RS ensures flexibility, speed, and efficiency in intralogistics. That’s why combining AS/RS with an automated pallet shuttle system has become one of the most powerful models in intralogistics.

From design to integration: every detail counts

AS/RS are designed with logistics needs in mind – from increasing storage density to integration with automation and digital control systems. Stacker crane systems efficiency hinges on meticulous design: lift capacity and movement speed define how many cycles per hour are possible, while storage racking type and height determine optimal vertical use.

ERP and WMS systems are the brains of warehouse logistics automation, ensuring quick and accurate flow of pallets or boxes.

Safety first: compliance with EN 528 and EN 15095 protects personnel and warehouse logistics rack equipment.

Continuous service throughout the racking automated stacker crane’s lifecycle ensures years of reliable movement without downtime.

Racking automated stacking cranes guarantee faster pallets and boxes flow, reliable warehouse logistics, and scalable automation.

KAPELOU warehouse logistics expertise: from automation project to its execution

At KAPELOU, we deliver end-to-end warehouse logistics automation. Our racking automated storage and retrieval system (AS/RS) ensures speed, accuracy, and safety of load movement. Our Miniload solutions integrate WMS/WCS to manage boxes and trays flow, synchronize stock, and monitor equipment in real time. A unified interface provides operational transparency, while Safety Integrated software safeguards people and machines. Combined with intelligent drives, KAPELOU rack automated storage and retrieval systems can boost productivity by up to 15%.

A long-term investment in warehouse logistics operation

Racking automated stacker crane is a non-stop operation: orders are processed precisely, goods follow exact routes, and every pallet or box flow is automatically tracked. Even during peak periods, same-day delivery is achievable.

Investing in automated storage and retrieval systems secures efficiency and safety at every racking storage level, reduces manual labor, and provides scalable warehouse logistics for long-term ROI.

Shift your rack-supported warehouse logistics operation into maximum productivity mode with KAPELOU. Contact us to find the optimal racking solutions for seamless boxes and pallets movement.

On August 19-20, 2025, our engineering team completed training at Dambach Lagersysteme (Germany), a manufacturer of storage and retrieval equipment...

In recent years, the warehouse has evolved far beyond being just a place to store goods. It is now a dynamic, technology-driven environment –...

On July 25, we joined the Logistics Summit in Lviv, organized by Alterra Group. The event became a platform for insightful discussions and the exch...

Close

Close

Back

Back

Close

Close