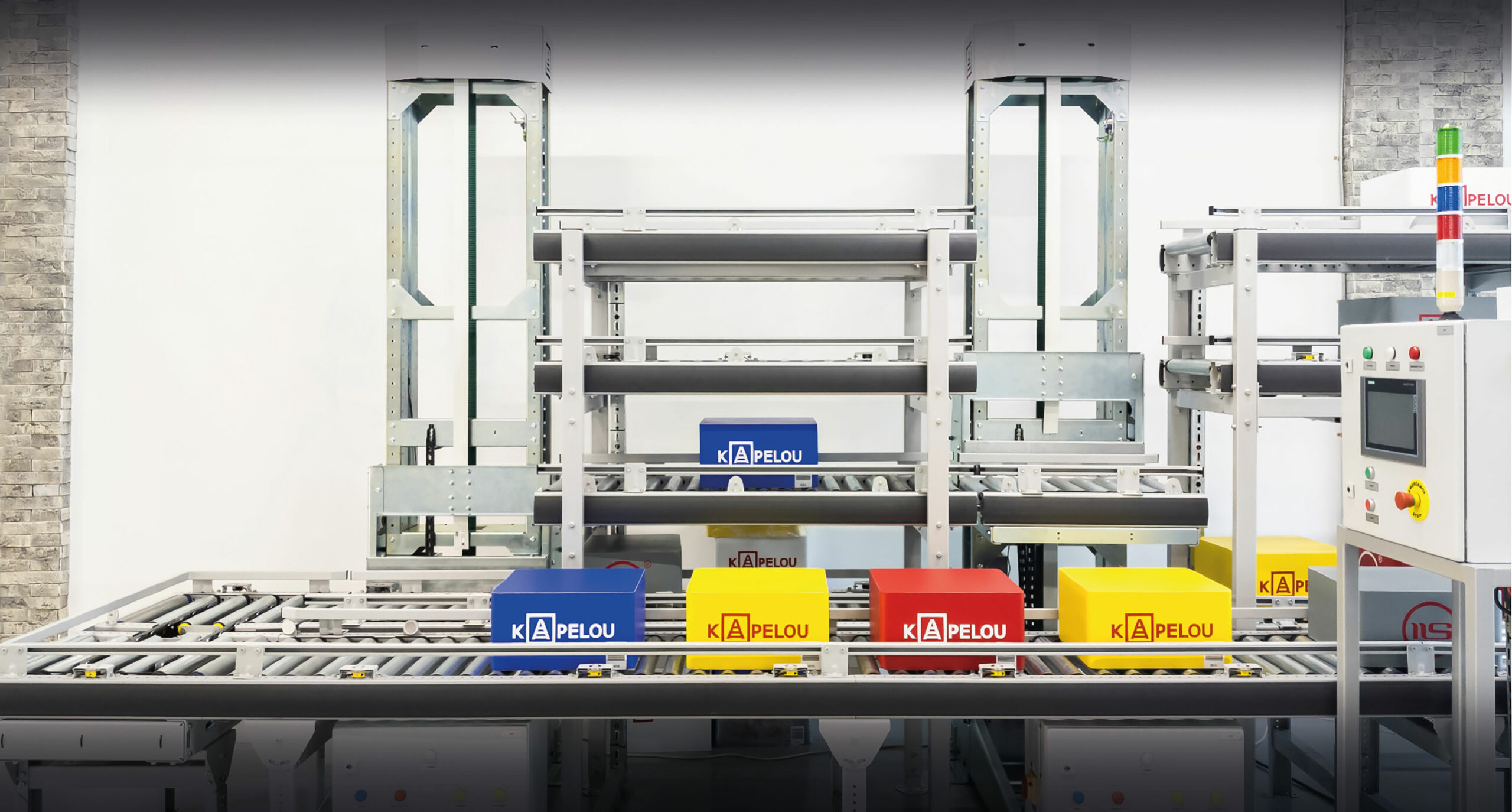

Buffer sequencer from KAPELOU: an efficient solution for fast and accurate sorting

KAPELOU develops and implements comprehensive solutions to increase warehouse productivity. One of these solutions is a buffer sequencer, consisting of driven conveyors, vertical conveyors for boxes, and sorting stations. The principle of its work is in the accumulation of orders on a certain basis according to the given logic of work through WMS.

The buffer sequencer is designed for highly dynamic warehouses of e-commerce, FMCG, production, and distributors. The buffer sequencer from KAPELOU organizes the packaging into a wave of orders (trays combined with one parameter) and sequentially delivers them to the sorter’s workplace in batches.

Buffer sequencer from KAPELOU:

- provides a fully automated process of serving trays with goods for ordering;

- compensates for the inequality of picking and sorting of goods in the warehouse;

- automatically generates a sequence of boxes according to the “wave” of orders;

- allows you to quickly sort, complete and transfer orders to the packaging area;

- allows you to effectively use storage space;

- gives a much larger number of processed orders in less time.

When implementing this solution, KAPELOU customers receive the list of benefits for their warehouse:

Advantage 1. The buffer sequencer can significantly increase the efficiency of the collection process thanks to the technology of “goods to person”. In the context of the logistics and supply chain sector, this modern method of order fulfillment combines automated storage with precise, ergonomic picking processes. The products are stored in the system and are automatically transported directly to the operator. Human-to-human technology is easily scaled according to growing demand or increasing items. Thus, the system:

- is ideal for ergonomic selection;

- is easily scalable;

- takes up less space.

Advantage 2. The sequencer buffer automates the formation of a “wave” of orders. This term means a set of orders or sub-orders that have common parameters. All orders and order wave trays are linked in the system by a single unique ID number. Wave aggregation is performed within the WMS, subject to system requirements and constraints.

Advantage 3. The buffer-sequencer solution increases the accuracy of selection, because it minimizes manual operations at the stage of completing orders.

Objectives of implementing solutions using a buffer sequencer in the client’s warehouse:

1. Compensation for uneven assembly and sorting. Occurs due to the accumulation (buffering) of trays with goods coming from the selection zones to the sorting zone at different speeds. This also includes the removal of empty boxes from the area of commodity sorting.

2. Maximum acceleration of the process of sorting, assembly and transfer to packaging. The sequence of issuing “waves” from the buffer is determined by WMS, TMS and is based on the logic of the priority of shipments of “waves” of orders according to the schedule of departure of the car. Lots of boxes come from different zones, “waves” and orders at different times. Delivery of certain batches is made consistently to sorters and in total forms the order or “wave” of orders.

3. Increasing the productivity of human labor. The supply of boxes is automatically set up, it takes place directly to the workplace of sorters on the principle of “goods to person”, which minimizes the involvement of human labor.

The complete solution from KAPELOU with the use of a buffer sequencer will help our customers to optimize warehousing processes to achieve maximum productivity of the warehouse.

Today, warehouse efficiency is measured in seconds, not hours. Modern warehouses are no longer just spaces packed with racks – they’re dynami...

On August 19-20, 2025, our engineering team completed training at Dambach Lagersysteme (Germany), a manufacturer of storage and retrieval equipment...

In recent years, the warehouse has evolved far beyond being just a place to store goods. It is now a dynamic, technology-driven environment –...

Close

Close

Back

Back

Close

Close