5 myths about warehouse process automation

The main task of any logistics company is to optimise the efficiency and speed of processing large customer orders, reduce costs and eliminate deficits. In addition, unused products in the warehouse cause costs, which has a negative impact on the company’s profit.

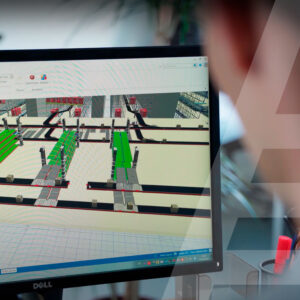

Automation of warehouse processes is essential for the efficient handling and storage of large quantities of goods. This allows work processes to be carried out with an accuracy of up to 99.99 % and minimises costs. Nevertheless, entrepreneurs often have doubts about the usefulness of automating warehouse logistics.

Myth #1: Automation requires high investment costs

The introduction of automated systems in warehouse logistics does indeed require a significant investment. However, don’t forget that the investment pays for itself in a relatively short time (provided reliable equipment is used). Experts recommend that large logistics centres already in operation gradually introduce automated systems in warehouse logistics and increase turnover in this way.

When a logistics company is faced with the following problems, it is time to automate the warehouse:

- incorrect execution of multi-line customer orders (mistakes are made in picking, etc.);

- execution of time-consuming workflows;

- hiring additional staff to check the accuracy of picking;

- inventory problems that make it difficult for the manager to rely on information about the available quantities of goods in the warehouse;

- problems in processing orders in a timely manner (delivery delays are not uncommon).

Warehouse automation is an innovative solution for carrying out labour-intensive operations that helps to increase the speed of operations, reduce errors, cut costs and increase the efficiency of a logistics company. Of course, if the warehouse has not used automation systems before, significant investment is required to modernise the business. Automation is a complex and multi-layered project. It involves a technical assessment, analysis and work planning and pays off 100 %.

Myth #2: Automation is time consuming and labor intensive

Experts recommend considering automated solutions from the very beginning, as upgrading an existing warehouse requires more time and investment. When experts take on the upgrading of a company, the manager is in any case presented with a solution concept that has the least possible impact on current operations.

In fact, warehouse automation is no longer such a complicated and expensive procedure today if one turns to professionals (such as KAPELOU) to have the necessary measures carried out. First, a detailed consultation takes place. This involves an analysis of the operating procedures. Specialists collect information, carry out investigations, analyse goods flows and SKU characteristics. The result is recommendations for improving warehouse logistics, both through process optimisation and automation.

The primary task of any logistics company is to reduce processing times, improve accuracy and quality, reduce the influence of the “human factor” and minimise the risk of errors.

The range of services in the field of optimising operations and warehouse automation includes:

- development, production and installation of equipment;

- development of software for warehouse automation;

- integration of the software product into the customer’s inventory system;

- commissioning of the equipment;

- implementation of the software and the warehouse management system in the company;

- technical instruction, training of personnel, professional support;

- warranty services.

KAPELOU’s professionals take on projects of any complexity. The company’s priorities are high-quality solutions and equipment. The engineers introduce innovative solutions not yet used in Ukraine and provide the best solutions to ensure efficient warehouse logistics. Our specialists develop the best solution for the customer to ensure an optimal flow of goods in their warehouse.

Myth #3: Automation requires high investment in staff training

On the contrary: automated warehouses are easy to operate. Employees do not have to be specially trained to do the work on the system. The tasks of the individual employees are clearly defined. When warehouse processes are automated, the influence of the “human factor” on operations is greatly minimised. This leads to the following improvements:

- reduction of the error rate when processing multi-line customer orders;

- acceleration of operational processes;

- improvement in the quality and accuracy of work.

Most automated storage solutions work according to the “goods to person” principle. The main task is the effective organisation of the operational process. It is important to shorten the path of the order picker and to avoid unnecessary movements. The use of such a system only makes sense on the condition that the processes of storing and picking goods are fully automated.

The principle of automation is simple: employees are assigned to a specific area and receive the goods only in their area. The goods move along the automation line (conveyors, sorting systems, etc.). The employees do not have to carry the goods with their hands. The picking process is fully automated.

The advantage of the “Goods-to-Person” principle is the time saved. In the “Person-to-Person” system, more than 50 % of the time is spent on the movement of the picker between the different picking stations, another 20 % on waiting times, i.e. forced downtimes, 20 % on documentation and 10 % on the removal of the goods from the picking station.

In addition, the “Goods-to-Person” system enables efficient use of staff resources. The employee is in a strictly limited work area and is responsible for performing specific tasks. The training period is shorter because the employee does not have to remember where and which items are in the warehouse.

Myth #4: The introduction of an automation system has a negative impact on the control of operations

On the contrary, the introduction of automation systems can eliminate many weak points in a company’s warehouse logistics. With WMS you can monitor the flow of goods, control the operation of the facility, control stocks, etc.

Myth #5: All warehouses need automation

Not all warehouses need automation. However, it is important for warehouses:

- with a wide range of products;

- with a high throughput.

Manual picking of multi-line customer orders is laborious and carries an increased risk of error. Modern technological advances offer a wide range of efficient solutions for warehouses of all kinds: e-commerce, automotive industry, pharmaceutical companies and distribution, manufacturers of car parts and other goods, retailers, postal and courier services. An individual approach to the implementation of each project is enormously important. KAPELOU develops solutions for the processes of storing and transporting goods, sorting and picking.

Today, warehouse efficiency is measured in seconds, not hours. Modern warehouses are no longer just spaces packed with racks – they’re dynami...

On August 19-20, 2025, our engineering team completed training at Dambach Lagersysteme (Germany), a manufacturer of storage and retrieval equipment...

In recent years, the warehouse has evolved far beyond being just a place to store goods. It is now a dynamic, technology-driven environment –...

Close

Close

Back

Back

Close

Close