Innovation backed by science: KAPELOU founder earns PhD

Can a business leader design warehouse automation technologies so advanced that they become subjects of academic research? At KAPELOU – absolutely.

On June 27, 2025, KAPELOU founder Oleksandr Klymenko successfully defended his dissertation titled “Models and Methods of Automated Control of a Robotic Conveyor-Based Sorting Line for Pharmaceutical Products” and earned a PhD in Automation and Computer-Integrated Technologies.

This milestone marks more than a personal achievement – it’s an indicator to the industry: today’s most effective warehouse automation technologies are born where engineering expertise meets academic depth and real-world experience.

Technologies recognized by science

The dissertation defense took place at Kharkiv National University of Radioelectronics (KNURE) – one of Ukraine’s top technical universities, recognized globally in the QS World University Rankings 2025. Nationally, KNURE ranks in the top 10 and holds 7th place among all technical universities in Ukraine.

Oleksandr’s research was supervised by Professor Ihor Nevliudov, head of the Department of Computer-Integrated Technologies, Automation and Robotics. He became the 41st PhD awarded under Prof. Nevliudov’s guidance – a testament to the academic rigor behind the work.

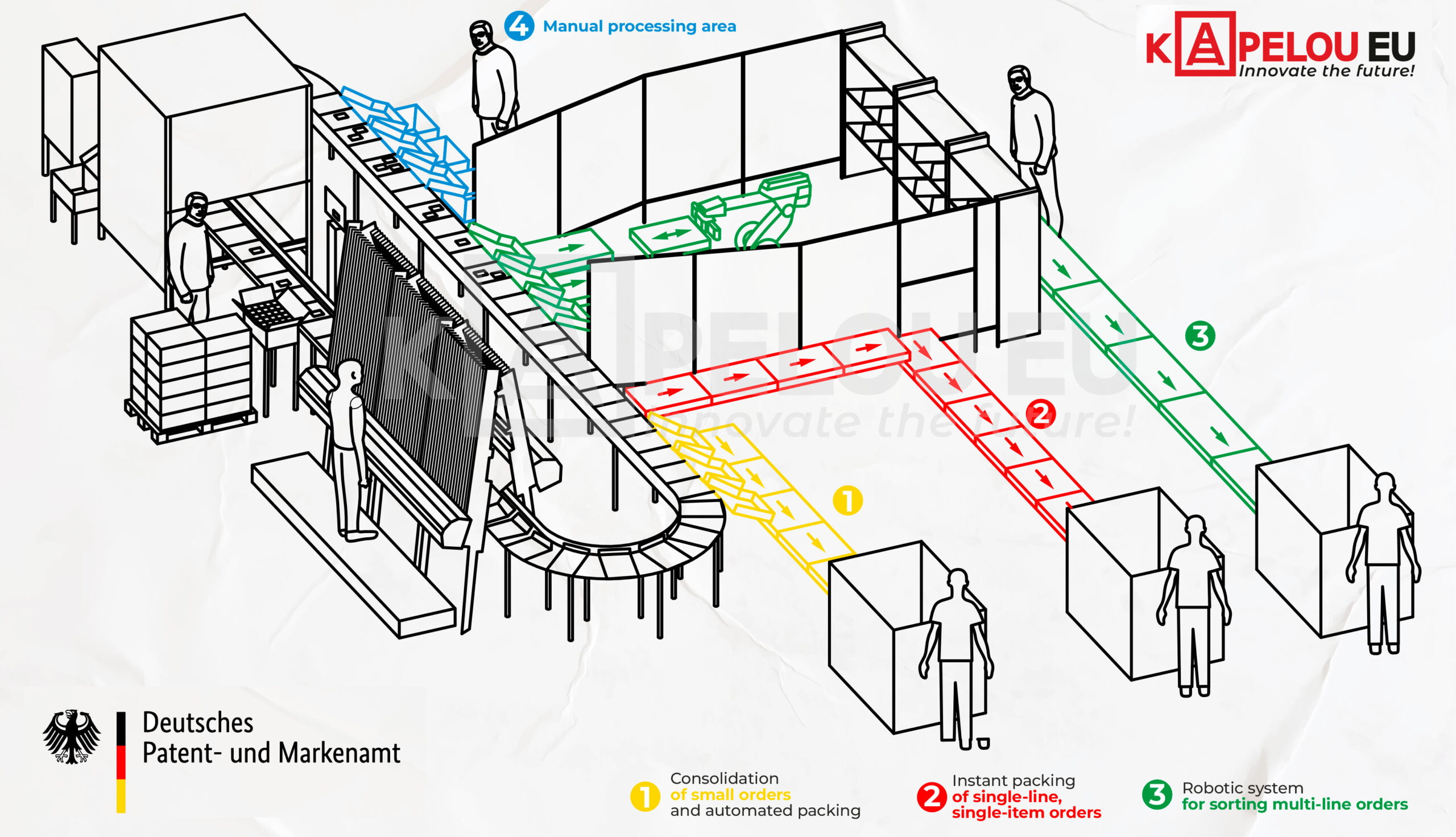

The dissertation combined scientific modeling with real-life case studies of warehouse automation projects. At the core of the research was a robotic sorting line for pharmaceutical goods. The line stands out for its innovation in package recognition, QR-code reading, and workload distribution between robots. Key components of the sorting line solution have been patented in Germany, underscoring the originality and value of the technology design.

The research wasn’t theoretical – it was based on an actual automated line for sorting, currently operating at warehouses of our European clients. The system’s efficiency has been validated in practice: the sorting line operates 25% faster, increasing overall order processing efficiency by over 18%. The technology makes the sorting line a powerful solution for high-throughput warehouse environments where speed and precision in sorting are critical.

Science-driven business: value for clients

We design technology using mathematical models and advanced control algorithms – and implement them in real-life warehouse projects, where every component is tested under operational conditions.

Our clients gain:

- validated systems with scientific approach and proven performance;

- access to cutting-edge technology that defines new industry standards;

- a partnership with a company committed to growing the next generation of professionals – since 2021, our KAPELOU educational lab has been operating at KNURE, providing hands-on training and internships with real equipment in a near-industrial environment.

The synergy of science and business is a true growth driver

The PhD achievement is a strong confirmation of our unique approach to automation – one that’s backed by proprietary scientific research and built around real challenges faced by the logistics industry.

Our systems address:

- workforce shortages;

- scalability demands;

- efficiency in sorting, processing, and order fulfillment.

Oleksandr Klymenko says: “Delivering technology on time, with guaranteed performance and full alignment with the client’s business goals – this is our strategic responsibility. Key to this is transparent communication, deep analysis of current processes, and accurate modeling of the warehouse’s future state after automation. The automated sorting line already proves its value in pharmaceutical logistics, but the underlying solution is fully scalable to other high-speed sectors – such as tobacco or FMCG”

Want to see how a scientific approach can power your warehouse? Drop us a comment – and we’ll show you how our automated sorting line helps industry leaders boost order processing speed and reduce reliance on manual labor.

Today, warehouse efficiency is measured in seconds, not hours. Modern warehouses are no longer just spaces packed with racks – they’re dynami...

On August 19-20, 2025, our engineering team completed training at Dambach Lagersysteme (Germany), a manufacturer of storage and retrieval equipment...

In recent years, the warehouse has evolved far beyond being just a place to store goods. It is now a dynamic, technology-driven environment –...

Close

Close

Back

Back

Close

Close